A Life-Changing Train Ride: The Birth of Renasens

Renasens was founded in September 2022 by Dr. Jade Abir Bouledjouidja, following her PhD research at Aix-Marseille University (Aix-en-Provence, France). Her doctoral work focused on using advanced technology for polymer extraction and impregnation, which she continued to explore in the context of textile waste separation later at KTH Royal Institute of Technology (Stockholm, Sweden). Motivated by the significant environmental impact of the textile industry and the limitations of existing large-scale recycling technologies, Dr. Jade established Renasens AB to pioneer a more sustainable solution. Her vision is to contribute to a future where the true value of resources is recognized and preserved.

Dr. Jade’s passion for sustainability, combined with her love for nature and outdoor activities, has driven her career. Since earning her chemical engineering degree, she has applied her technical expertise to develop bio-based alternatives to fossil-based products. In early 2022, while traveling to Copenhagen, a conversation with a fellow train passenger about the textile waste crisis heightened her awareness of the global challenges surrounding textile recycling. This interaction sparked further research into the state of textile waste management, confirming the absence of scalable solutions for closed-loop fibre recovery, particularly from mixed textile waste.

Inspired to make a difference, Dr. Jade expanded her research at KTH, focusing on developing processes to extract dyes, additives, and separate fibres from textiles. This work resulted in two patent applications and laid the foundation for Renasens.

With over 10 years of experience in developing sustainable alternatives to fossil-based products and plastic recycling, Dr. Jade holds a chemical engineering degree and a PhD in material science and green processes. Renasens’ technical team includes research engineers Vijaya Lakshmi Vegunta and Antonia Von Schreeb, both with chemistry backgrounds from KTH Royal Institute of Technology. The company is actively expanding, currently recruiting a business manager, operations manager, and two additional engineers.

The name "Renasens" reflects the company's mission, blending “renew” with the idea of giving “sense” or higher purpose to the work the team is undertaking.

Innovative Waterless & Clean Technology for Textile Waste Recycling

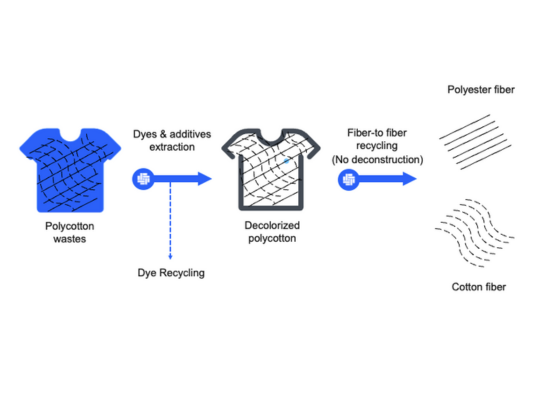

Renasens is developing a groundbreaking waterless technology to recycle blended textile waste, transforming it into valuable new resources. The technology also enables the extraction of dyes and additives from textiles before recycling, providing a comprehensive solution for the fashion and textile industries to manage end-of-life products and create circular raw materials. This innovation addresses key environmental challenges, such as reducing textile waste in landfills, mitigating microplastic release, and preventing water pollution caused by textile production.

“At the heart of Renasens’ process is the use of subcritical and supercritical fluids as solvents, eliminating the need for water,”

explains Dr. Jade. Their approach allows for the efficient extraction of dyes and additives from textile waste, followed by the recycling of not only pure fibres like cotton, but also complex blends such as polycotton and cotton-acrylic. Most importantly, Renasens’ technology preserves fibre quality at the macromolecular level without deconstruction or depolymerization, making it highly energy-efficient. Current market solutions rely on mechanical recycling, which often results in shorter, lower-quality fibres, or chemical recycling that consumes large amounts of energy by breaking down polymers to monomers. In contrast, Renasens' technology offers a more sustainable, high-quality alternative.

One of the main challenges for Renasens is handling the inconsistent feedstock in their recycling reactor. Even though polycotton waste is sorted at textile facilities, materials like spandex and acrylic labels can still be present, affecting output quality. To address this, the company is actively collaborating with stakeholders across the textile value chain to create a fully circular recycling process.

“Competing with virgin fossil-based products is difficult, and achieving competitiveness at scale is one of our key goals,”

states Dr. Jade. Renasens’ mission is deeply rooted in sustainability, aligning with several of the UN's Agenda 2030 goals. By using clean, waterless, and energy-efficient technology to recover fibres and extract dyes, the company promotes the revalorization of resources within planetary boundaries. This process protects textile workers from exposure to harmful chemicals (SDG3), reduces water usage and pollution (SDG6), and supports economic growth without environmental degradation (SDG8). Renasens also contributes to sustainable consumption and production patterns (SDG12) and combats climate change by preventing the incineration of textile waste, which would otherwise release significant CO2 emissions (SDG13).

Next Steps at Renasens

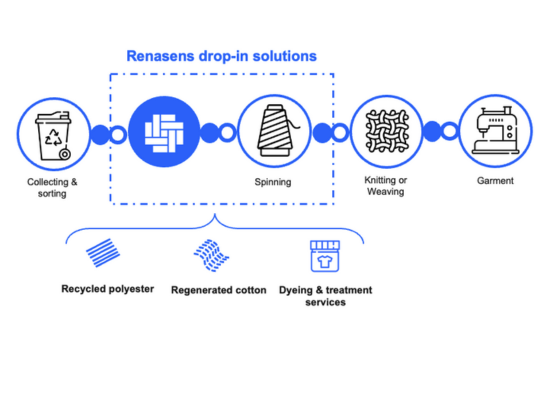

Renasens is currently focused on raising funds and scaling up its innovative recycling technology. The company is also expanding its team and seeking new partnerships within the textile value chain. They are already collaborating with several startups involved in textile waste collection, sorting, spinning, and fabric production.Looking ahead, Renasens plans to build a pilot plant, strengthen its team, and secure additional commercial partnerships. Their goal is to bring their sustainable recycling solutions to a larger market.

Joining the ISC3 Global Start-up Service as one of the Innovation Challenge 2024 finalists, Renasens' innovative approach actively contributes to SDG 3 (Good Health and Well Being), SDG 6 (Clean Water and Sanitation), SDG 8 (Decent Work and Economic Growth), SDG 9 (Industry, Innovation, Infrastructure), SDG 12 (Responsible Consumption and Production), SDG 13 (Climate Action).